The world's first dry* scroll vacuum pump

ANEST IWATA introduced the world's first "dry (=oil-free) scroll vacuum pump" in 1993. It offered a number of advantages over vacuum pumps with conventional technologies, such as compact size, better ultimate pressure, quieter and less vibration during operation and an energy-saving function. To date, dry scroll vacuum pumps have been widely used in all branches of industry, such as physics and analytical equipment, semi-conductor processing, automotive and aerospace experiments. The basic concepts of air compressors and vacuum pumps were similar, but not in the way engineers initially thought. As the development project was started from scratch, engineers faced many difficult situations at almost every stage of development, as it was the world's first dry scroll vacuum pump. Project team member at the time, Masaru Tsuchiya, who is now a member of the Vacuum Equipment Development Group, shares insights into the story.

ANEST IWATA introduced the world's first oil-free scroll vacuum pump in 1993, two years after the launch of the scroll compressor. Can you please tell us what motivated ANEST IWATA to start developing vacuum pumps?

In the 1980s, we were looking for new business outside of the existing sprayer and air compressor industries. While the compressor development team started the project with oil-free scroll technologies, our team thought it should also work as a vacuum pump. Both projects were started at the same time, but moved forward separately. As a result, it took us as a vacuum pump development team about five years to introduce the world's first dry scroll vacuum pump.

Can you please tell us what was the most complex and time-consuming

process during the development?

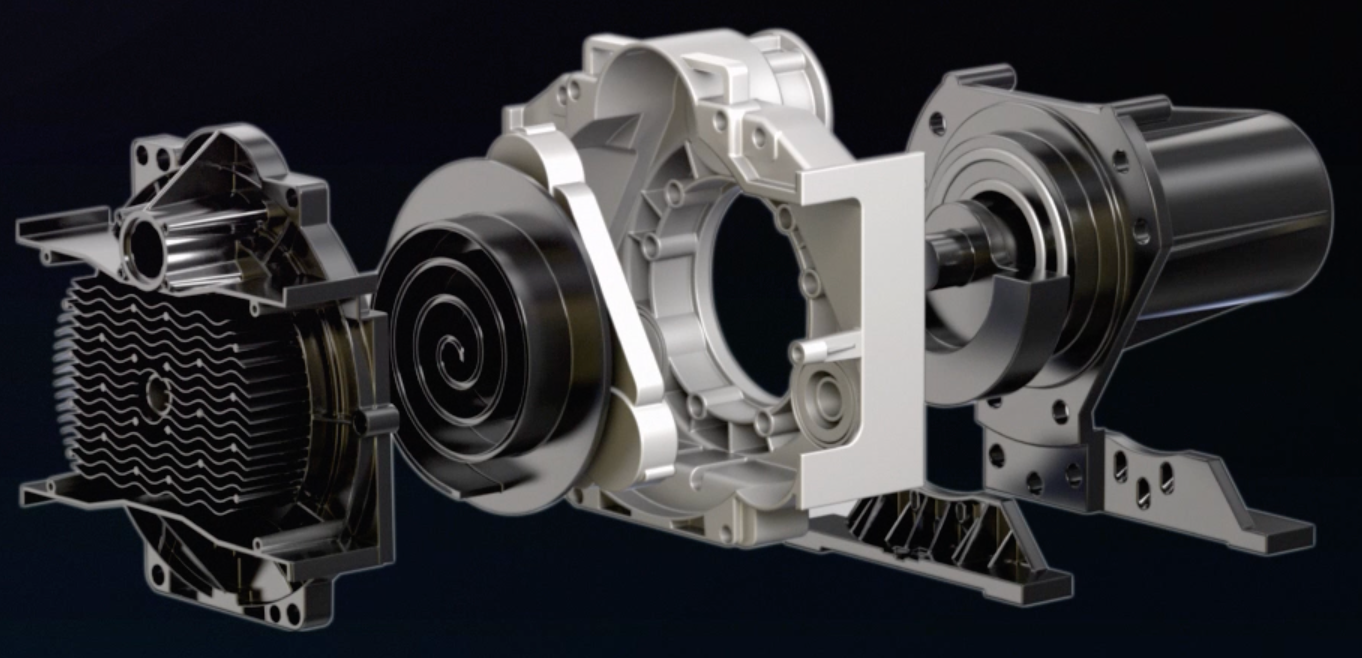

First, I would like to explain the difference between air compressors and vacuum pumps: Compressors draw in atmospheric air and compress it many times over to increase the pressure. Vacuum pumps, on the other hand, "reduce the pressure" of the inlet and a sealed container connected to it. This means that the pump creates a vacuum by collecting a certain number of gas molecules and removing them from the container.

We adopted the same principle, but the physical load on the pump bodies was different, as one pump did the compressing to increase the pressure, while the other was for pumping down to decrease the pressure. In other words, the function and strength of the components are different for compressors and vacuum pumps. In our investigation, we found that they also behaved differently. Many components looked the same, but we had to test and examine them first. In the process, we had to reinvent almost all of the parts to fit the vacuum application. For example, we researched sealing material, which we required to have a certain strength and repulsion because it needed to function in the atmospheric pressure range and one hundred thousandth of that.

Operating condition of the ISP (dry scroll vacuum pump)

*Statement is based on our own study on the industrial oil-free scroll compressor larger than 0.75 kW or the industrial oil-free scroll vacuum pump larger than 0.1 kW.